Flexibility

Oligomers for Flexibility

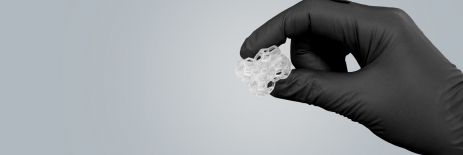

Various Bomar® oligomers can be used to impart flexibility to coatings, inks, and pressure-sensitive adhesives (PSAs). These flexible oligomers can be used as the main oligomer or as a co-oligomer and are used in applications ranging from thermoformable coatings to highly stretchable inks and 3D printing resins.

Flexibility in an oligomer is important for 3D printing resins as it can print fine details across a range of material options with an excellent surface finish. In addition, many of our materials are jettable for multi-colored 3D models. Additionally, our polyether acrylates typically have very good overall dynamic properties and surface cure.

Need more information? Our technical experts are on hand to help troubleshoot and recommend the perfect Bomar solution

Oligomer Product Finder

Quickly narrow down our Oligomer product offering by selecting your formulary requirements. From there you can compare, download product datasheets, and request a sample.

Related Products

These oligomers are designed with flexibility in mind. Click the box to get detailed product information.

-

BRC-4421MBRC-4421M: Difunctional Aliphatic Hydrophobic Urethane Methacrylate

Imparts toughness for impact-resistant 3D printing resins with excellent flexibility. Low color and adhesion to many plastics.

-

BRC-843DBRC-843D: Difunctional Aliphatic Hydrophobic Urethane Acrylate

Improves adhesion, enhances hardness. High temperature resistance for nail gels and coatings.

-

BR-7432GBBR-7432GB: Difunctional Aliphatic Polyester Urethane Acrylate Oligomer

Provides impact resistance and toughness and has excellent adhesion to various substrates.

-

BR-345BR-345: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

Provides unique properties such as color stability for better aesthetics in 3D printing resins.

-

BR-744BTBR-744BT: Difunctional Aliphatic Polyester Urethane Acrylate Oligomer

Oligomer with excellent adhesion, toughness, and flexibility for 3D printing resins and coatings.

-

BR-541SBR-541S: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Color stable, optically clear oligomer with a desirable balance of toughness and flexibility.

-

BR-643BR-643: Difunctional Aliphatic Polybutadiene Urethane Acrylate Oligomer

Polybutadiene urethane acrylate designed to meet rigorous electronic applications.

-

BR-116BR-116: Trifunctional Aromatic Polyether Urethane Methacrylate Oligomer

Used in the manufacture of soft coatings and adhesives made to adhere to metals and glass.

-

BR-572SLBR-572SL: Modified Aliphatic Polyether Urethane Acrylate

Functionalized to promote adhesion. Has enhanced flexibility, toughness, and fatigue properties.

-

BR-204BR-204: Difunctional Aromatic Polyether Urethane Methacrylate Oligomer

High bond strength, low color oligomer used to formulate many different UV adhesive applications.

-

BR-641TFBR-641TF: Difunctional Aliphatic Polybutadiene Urethane Acrylate

Designed to meet rigorous electronic applications. Has excellent dielectric properties.

-

BR-641SBR-641S: Difunctional Aliphatic Polybutadiene Urethane Acrylate

Offers excellent dielectric properties, high temperature resistance, and hydrophobic character.

-

BRS-14320SBRS-14320S: Difunctional Aliphatic Silicone Urethane Acrylate Oligomer

Low shrinkage difunctional oligomer that imparts softness, flexibility, and temperature resistance.

-

XR-145SXR-145S: Trifunctional Aliphatic Polyether Urethane Methacrylate Oligomer

A high molecular weight provides low formulation viscosity and moderate elongation for coatings.

-

BR-202BR-202: Difunctional Aromatic Polyether Urethane Methacrylate Oligomer

An oligomer with strong bond strength, hydrolytic stability, and adhesion to diverse substrates.

-

BR-302BR-302: Difunctional Aromatic Polyether Urethane Acrylate Oligomer

Oligomer used for interior and floor coatings where yellowing constraints are not present.

-

BR-3042BR-3042: Difunctional Aromatic Polyether Urethane Acrylate Oligomer

Increases flexibility and enhances adhesion to plastic substrates in UV adhesive applications.

-

BR-344BR-344: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Non-yellowing, high molecular weight oligomer for flexible, durable roof and floor coatings.

-

BR-3641AABR-3641AA: 1.3 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Aliphatic polyether urethane acrylate with a high molecular weight and theoretical 1.3 functionality.

-

BR-3641AJBR-3641AJ: 1.3 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Ideal candidate for adhesion promoter, reactive tackifier, or optically clear UV-PSAs.

-

BR-372BR-372: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Offers a balance of toughness and flexibility, with very low color for plastic and wood coatings.

-

BR-374BR-374: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

A material that offers a balance of toughness and flexibility for roof and floor coatings.

-

BR-3741AJBR-3741AJ: 1.3 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Excellent candidate for consideration in UV light curable PSAs as a reactive tackifier.

-

BR-3747AEBR-3747AE: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Non-yellowing oligomer that enhances flexibility and improves adhesion to unusual substrates.

-

BRC-441DBRC-441D: Difunctional Aliphatic Hydrophobic Urethane Acrylate Oligomer

Ultra-low water absorption for moisture-sensitive or hydrophobic applications.

-

BRC-4421BRC-4421: Difunctional Aliphatic Hydrophobic Urethane Acrylate Oligomer

Excellent plastics adhesion and hydrophobicity for temperature-resistant coatings and resins.

-

BRC-443BRC-443: Difunctional Aliphatic Hydrophobic Urethane Acrylate Oligomer

Oligomer for glass, plastic, & steel coatings and inks. High temperature resistance, low yellowing.

-

BRC-443DBRC-443D: Difunctional Aliphatic Hydrophobic Urethane Acrylate

Low water absorption, non-yellowing hydrophobic urethane acrylate for nail gels and coatings.

-

BR-543BR-543: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Enhances flexibility, provides oil and chemical resistance, and exhibits hydrolytic stability.

-

BR-543MBBR-543MB: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

Excellent adhesion, optical clarity for nail & optical coatings. Adhesion promoting co-oligomer.

-

BR-543TFBR-543TF: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Tin-free, abrasion-resistant oligomer with enhanced flexiblity for film and foil coatings.

-

BR-551MBR-551M: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

Oligomer that provides excellent acetone removability when used in gel polish applications.

-

BR-551MEBR-551ME: 1.5 Functional Aliphatic Polyether Urethane Methacrylate Oligomer

Oligomer that provides excellent acetone removability when used in gel polish applications.

-

BR-571BR-571: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Improves solvent resistance and weatherability. Used to formulate pigmented and wood coatings.

-

BR-571MBBR-571MB: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

Designed to formulate scratch-resistant and hard glossy coatings. Offers toughness and flexibility.

-

BR-581MTBR-581MT: Difunctional Aliphatic Tack-Free Topcoat Oligomer

Oligomer blend that provides a low color, tack-free cure under low-intensity LED cure conditions.

-

BR-582I10BR-582I10: 2.4 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Provides a balance of toughness and flexibility to coating formulations for plastics and metal.

-

BR-640DBR-640D: Difunctional Aliphatic Polybutadiene Urethane Acrylate Oligomer

Excellent dielectric properties and radiation curability for rigorous electronic applications.

-

BR-641DBR-641D: Difunctional Aliphatic Polybutadiene Urethane Acrylate Oligomer

Designed to meet rigorous electronic coating applications. Has excellent hydrophobic properties.

-

BR-641EBR-641E: Difunctional Aliphatic Polybutadiene Urethane Acrylate Oligomer

Offers high temperature resistance and excellent flexibility for electronic coatings, inks and PSAs.

-

BR-742MBR-742M: Difunctional Aliphatic Polyester Urethane Methacrylate Oligomer

Has a balance of hardness and flexibility, low heat generation during cure, and improves adhesion.

-

BR-742MSBR-742MS: Difunctional Aliphatic Polyester Urethane Acrylate Oligomer

Nail coating oligomer with an excellent balance of gloss, low color, removability, and durability.

-

BR-7432GI30BR-7432GI30: Difunctional Aliphatic Polyester Urethane Methacrylate Oligomer

Imparts incredible toughness and flexibilty, making it ideal for impact and bend-resistant coatings.

-

BR-744SDBR-744SD: Difunctional Aliphatic Polyester Urethane Acrylate

Excellent flexibility, tensile strength, and adhesion to various substrates. For PSA, coatings, inks.

-

BRC-843BRC-843: Difunctional Aliphatic Hydrophobic Urethane Acrylate

High temperature resistance and non-yellowing for coatings and inks for glass, plastic, and steel.

-

BRC-843SBRC-843S: Difunctional Aliphatic Hydrophobic Urethane Acrylate

Softer, more flexible version of BRC-843. Enhances hardness in ink and coating applications.

-

BRC-843SD1BRC-843SD1: Difunctional Hydrophobic Urethane Acrylate

Enhances hardness and improves adhesion in coatings and inks for plastic, glass, and steel.

-

BR-970BTBR-970BT: Difunctional Aliphatic Urethane Acrylate Oligomer

Low viscosity oligomer with excellent cure response for rapid prototyping 3D printing resins.

-

BR-990BR-990: Trifunctional Aliphatic Urethane Acrylate Oligomer

Can be used effectively in performance coating applications needing a greater degree of flexibility.

-

BR-5825I30BR-5825I30: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Low viscosity equivalent to BR-582 offering an excellent combination of toughness and flexibility.

-

BR-1041MBBR-1041MB: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

BR-1041MB is a biobased polyether urethane methacrylate oligomer with a substantial amount of biobased content and is tin-free. This is a harder version of BR-1043MB. This oligomer has a good balance of toughness and flexibility. It has the ability to adhere to a variety of plastic substrates. The biobased backbone, methacrylate functionality and tin-free nature make this an excellent choice for consumer applications with low irritancy.

-

BR-573MBR-573M: Difunctional Aliphatic Polyether Urethane Methacrylate

BR-573M is a tin-free difunctional aliphatic polyether urethane methacrylate. BR-573M is an excellent candidate to consider for use in tough 3D printing resins or nail gel applications. As a primary oligomer, BR-573M offers excellent properties of hardness, adhesion and optical clarity. As a co-oligomer, BR-573M can be used to improve an existing formulation’s adhesion and impact resistance. This product has low skin sensitivity and good optical properties.

-

BR-5541MDBR-5541MD: Difunctional Aliphatic Polyether Urethane Methacrylate

Flexible polyether urethane methacrylate oligomer diluted in 20% IBOMA with a low modulus, good adhesion to a variety of substrates, and excellent elasticity. The high molecular weight of the backbone structure offers improved elasticity and rebound versus similar high elongation materials. The low modulus of the material allows for a high degree of flexibility comparable to silicone-based materials. The compressibility of the material also offers potential usage in gasket and sealing applications.

-

BR-1044MBBR-1044MB: Difunctional Aliphatic Polyether Urethane Methacrylate

BR-1044MB is a bio-based polyether urethane methacrylate with a majority (>80%) percentage of bio-based content. Compared to similar petrochemical-based materials, BR-1044MB combines a lower viscosity with similar flexibility, elasticity, and softness. This resin brings excellent resiliency with impact properties to formulations along with improved compatibility of all components.

-

BR-1043MBBR-1043MB: Difunctional Aliphatic Polyether Urethane Methacrylate Oligomer

Bio-based oligomer with high bio-based content, low modulus, and low temperature flexibility.

-

BR-582BR-582: 2.4 Functional Aliphatic Polyether Urethane Acrylate

BR-582 is a 2.4 average functional aliphatic polyether urethane acrylate. As with other BR-500 series materials, BR-582 is designed to offer a balance of benefits between toughness and flexibility. While only slightly lower in tensile strength and hardness than BR-571, BR-582 has almost double the total elongation at break. BR-582 responds quickly to UV cure, owing to its elevated functionality.

-

BDT-1006BDT-1006: Hexafunctional Thioether Dendritic Acrylate Oligomer

Designed for hard coatings, OPVs, and printing inks. Very good chemical and thermal resistance.

Get In Touch

Have questions? Need more information? We're here to help.