Cure Speed

UV/EB Rapid Curing Oligomers

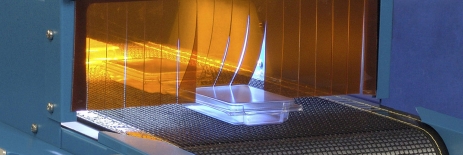

Bomar® UV/EB fast light-curing oligomers utilize reactive diluents (monomers) that allow properties to develop immediately, resulting in a full cure in seconds. This also creates a greater depth of cure-all at a lower price point than other curing methods.

High cure speed is particularly important for applications such as 3D printing, inks, and industrial coatings as well as for nail coatings and adhesives.

Bomar light-curing oligomers cure in three ways:

- UV/EB (ultraviolet) light: 200-400 nm (broad-spectrum)

- LED light: 365, 385, or 405 nm

- Visible light: typically 380-450 nm (no curing equipment needed)

UV and LED offer many advantages such as creating efficient line speeds for faster curing with more PI. They also produce scratch-resistant coatings, don’t use any VOCs, and are compatible with nonporous substrates like plastics and metals.

Looking for post-curing methods? We recommend Dymax light cure flood and spot lamps.

- Flood lamps: used for when the material is in the green state, just off the printer

- Broadband UV and LED spot curing

- Cure small areas of 3D printed materials

- Repairs

- Cure two intricate pieces together to create larger assemblies

Need more information? Our technical experts are on hand to help troubleshoot and recommend the perfect Bomar solution.

Oligomer Product Finder

Quickly narrow down our Oligomer product offering by selecting your formulary requirements. From there you can compare, download product datasheets, and request a sample.

Related Products

These products contain UV/EV cure properties. Click the box to get detailed product information.

-

BR-940BTBR-940BT: Difunctional Aliphatic Urethane Acrylate

Tin-free low molecular weight oligomer offering excellent adhesion, flexibility, and balanced hardness.

-

BR-541SBR-541S: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Color stable, optically clear oligomer with a desirable balance of toughness and flexibility.

-

BR-144BBR-144B: Trifunctional Aliphatic Polyether Urethane Acrylate Oligomer

Non-yellowing oligomer with rapid cure speed for coatings and graphic arts applications.

-

BDT-4330BDT-4330: 30 Functional Thioether Dendritic Acrylate Oligomer

Excellent chemical, thermal, scratch, and abrasion resistance for coatings, OPVs, and printing inks.

-

BR-571BR-571: Difunctional Aliphatic Polyether Urethane Acrylate Oligomer

Improves solvent resistance and weatherability. Used to formulate pigmented and wood coatings.

-

BR-582E8BR-582E8: 2.4 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Develops impact resistance. Suggested for use in single-coat, flexible coatings on plastic & metal.

-

BR-582I10BR-582I10: 2.4 Functional Aliphatic Polyether Urethane Acrylate Oligomer

Provides a balance of toughness and flexibility to coating formulations for plastics and metal.

-

BR-941BR-941: Difunctional Aliphatic Polyester Urethane Acrylate Oligomer

For applications requiring very fast cure response for adhesives and non-yellowing for coatings.

-

BR-970BTBR-970BT: Difunctional Aliphatic Urethane Acrylate Oligomer

Low viscosity oligomer with excellent cure response for rapid prototyping 3D printing resins.

-

BR-970HBR-970H: Difunctional Aliphatic Urethane Acrylate Oligomer

Low viscosity, rapid curing, non-yellowing oligomer ideal for 2D and 3D inkjet applications.

-

BR-990BR-990: Trifunctional Aliphatic Urethane Acrylate Oligomer

Can be used effectively in performance coating applications needing a greater degree of flexibility.

-

BDT-1015BDT-1015: 15 Functional Thioether Dendritic Acrylate Oligomer

Low shrinkage and warpage. Excellent scratch, chemical, and stain resistance for coatings & inks.

-

BDT-1006BDT-1006: Hexafunctional Thioether Dendritic Acrylate Oligomer

Designed for hard coatings, OPVs, and printing inks. Very good chemical and thermal resistance.

Get In Touch

Have questions? Need more information? We're here to help.