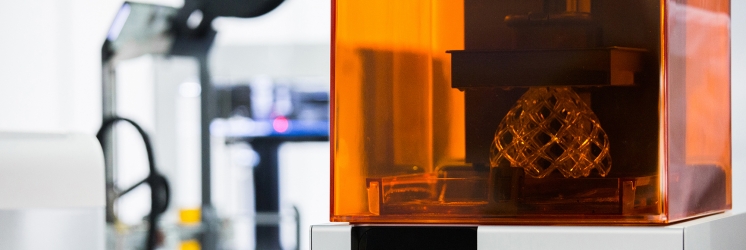

3D Printing

Bomar Oligomers for 3D Printing Formulations

Bomar® 3D printing light-sensitive urethane (meth)acrylate oligomers are designed specifically to create rigid, tough, and flexible 3D printing resins and inks with superior mechanical properties that are used in Stereolithography (SLA), Digital Light Processing (DLP), and 3D inkjet applications. These oligomers cure with UV/EB light energy and when formulated into a photopolymer resin can greatly affect the flexibility, chemical and impact resistance, and tensile strength of parts made from the resin.

Bomar oligomers provide a wide range of mechanical properties to meet the needs of the many emerging 3D printing applications. Ancillary properties such as low shrinkage, low moisture absorption, low-to-high glass transition temperatures, and low viscosity can also be provided to accommodate each unique application. Formulators can utilize them in their 3D printing resins and inks to create new, higher-quality printing materials and to overcome challenges associated with clarity and color stability, object deformation, and the surface quality of 3D printed parts.

Bomar 3D printing oligomers are used in a wide range of industries and are especially suited for use in rapid prototyping and manufacturing of final 3D printed products.

Flexible 3D Printing Formulations

Flexible and tear-resistant 3D printing resins are finding broader use in a wide range of applications, from sneakers and helmet lattices to rubber prototypes. Some parameters that are important to creating flexible 3D printing formulations include lower glass transition temperature, higher modulus, and low moisture absorption.

- Low modulus with high elongation

- Rebound capability (viscoelasticity/ductility)

- Tack-free surfaces

- Flexible

Rigid 3D Printing Inks and Resins

High rigidity and tensile strength are key needs for many 3D printing applications. Rigid resins with tensile strengths exceeding 85 MPa and HDTs >120°C can be formulated using Bomar oligomers, and different needs such as tin-free products, improved hydrophobicity, low ash content, or low viscosity can also be met.

- High tensile strength

- Hard

- Low viscosity

- High HDTs

- Tin-free options

Tough 3D Printing Inks and Resins

Formulating 3D printing resins and inks to provide a high level of toughness while maintaining a workable formulation viscosity is a challenge. Bomar oligomers can be used to improve the tensile strength in 3D printing materials and create a formulation that is tough with high impact strength and elongation.

- Reasonable viscosity with ability to obtain desired properties

- Higher elongation than rigid materials with a lower tensile strength - not as hard

- Balanced tensile strength with elongation

Bomar Oligomers for 3D Printing Video

Quality 3D printing formulations have low viscosity, fast cure speeds, varying strengths & flexibility. The oligomeric backbone structure is key in the formulations. Bomar oligomers are designed to maintain critical mechanical properties in various 3D printing resins including rigid, tough, and flexible formulations. This enables Bomar oligomers to help developments be made in industries such as dental, aerospace, and automotive.

Toll Manufacturing

Bomar partners with all size companies searching for a reliable and knowledgeable raw chemical contract manufacturing partner. Our 30+ years of experience manufacturing oligomers and resins, intermediate coatings, and other chemical materials gives us the technical background and expertise needed for successful toll manufacturing relationships.

Supporting Equipment

Dymax designs and manufacturers dispense and light-curing systems. These systems are optimized to work seamlessly with Bomar oligomers to gain process efficiencies by delivering rapid surface cure, depth of cure, and speed of cure in an economical way.

Get In Touch

Have questions? Need more information? We're here to help.